Types of Cabinet Paint and Scratch Resistance

The selection of paint for kitchen cabinets significantly impacts their longevity and aesthetic appeal. Understanding the properties of different paint types and their respective scratch resistance is crucial for achieving a durable and visually pleasing finish. This section will analyze the performance characteristics of various cabinet paints, considering factors such as durability, application ease, and cost. The influence of paint sheen on scratch visibility will also be explored.

Comparison of Cabinet Paint Types

The choice of paint significantly affects the scratch resistance of kitchen cabinets. Several factors, including chemical composition and application method, contribute to overall durability. The following table summarizes the key characteristics of common cabinet paint types:

| Paint Type | Durability/Scratch Resistance | Ease of Application | Cost |

|---|---|---|---|

| Oil-Based | High; forms a hard, durable finish resistant to scratches and abrasions. | More challenging; requires solvents for cleanup and longer drying times. | Generally higher than water-based options. |

| Latex (Water-Based Acrylic) | Moderate; offers good durability but may be less scratch-resistant than oil-based paints. | Easy; water cleanup and faster drying times. | Generally lower than oil-based options. |

| Acrylic Enamel | High; provides a hard, smooth finish with excellent scratch resistance. Often used in high-traffic areas. | Moderate; similar to latex in application but with potentially longer drying times depending on the formulation. | Moderately priced; often a balance between performance and cost. |

| Alkyd Enamel | High; similar to oil-based paints in durability and scratch resistance. | Moderate; requires solvents for cleanup. | Generally higher than water-based options. |

Impact of Paint Sheen on Scratch Visibility

The sheen level of the paint significantly influences the visibility of scratches. A higher sheen reflects more light, making imperfections more noticeable. Conversely, lower sheens mask scratches more effectively.

Cabinet paint scratches easily – The following points illustrate the relationship between sheen and scratch visibility:

- Matte/Flat: Hides scratches exceptionally well due to its non-reflective surface. However, it is more prone to staining and less durable.

- Satin: Offers a good balance between scratch concealment and durability. Scratches are less visible than on gloss finishes.

- Semi-Gloss: Provides a moderate level of scratch concealment. More durable than satin but scratches are more apparent.

- Gloss: Highly reflective; scratches are very visible. Offers the highest durability but shows imperfections readily.

Chemical Composition and Scratch Resistance, Cabinet paint scratches easily

The chemical composition of different paint types directly affects their scratch resistance. Oil-based paints, for instance, typically contain alkyd resins that form a hard, durable film upon drying. This hard film provides excellent resistance to scratches and abrasions. Latex paints, primarily composed of acrylic polymers, generally form a less hard film, resulting in lower scratch resistance compared to oil-based paints. Acrylic enamel paints, however, often incorporate additives and specialized resins to enhance their hardness and durability, improving scratch resistance significantly. The specific formulation, including the type and concentration of resins, pigments, and additives, significantly influences the final film’s physical properties and, consequently, its resistance to scratching. For example, the inclusion of certain cross-linking agents can increase the density and hardness of the paint film, enhancing scratch resistance.

Preventing and Repairing Scratches: Cabinet Paint Scratches Easily

Minimizing scratches on painted cabinets requires careful attention to both the painting process and post-painting protection. Proper preparation and application techniques significantly reduce the likelihood of scratches during use, while preventative measures and effective repair methods address unavoidable minor damage.

Applying Cabinet Paint to Minimize Scratches

Careful surface preparation and precise application techniques are crucial for minimizing scratches on painted cabinets. The following steps provide a comprehensive guide to achieving a durable, scratch-resistant finish.

- Thorough Cleaning: Begin by thoroughly cleaning the cabinet surfaces with a degreasing agent to remove any dirt, grease, or grime. This ensures optimal paint adhesion.

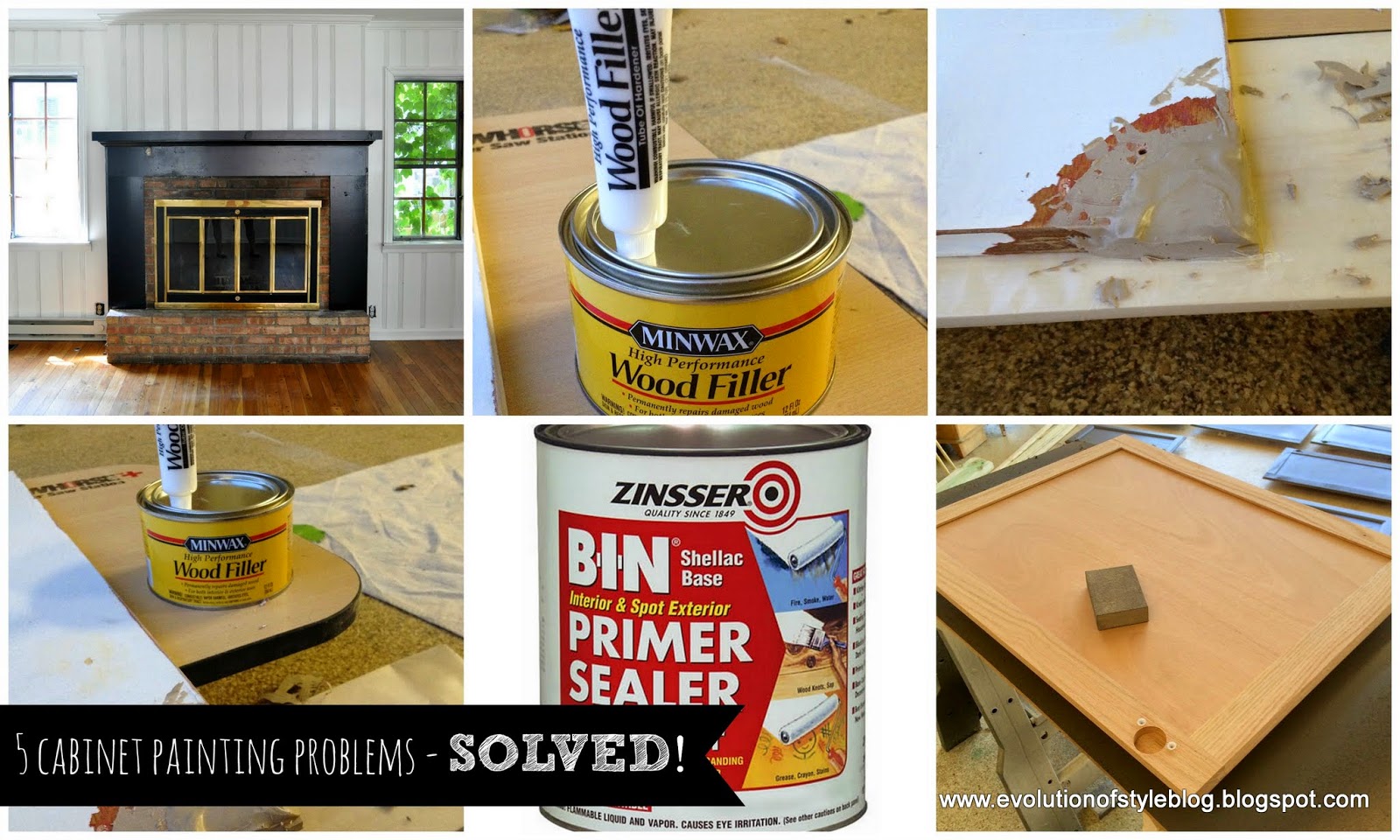

- Surface Preparation: Sand the cabinet surfaces with fine-grit sandpaper (180-220 grit) to create a smooth, even surface. This removes any imperfections and improves paint adhesion. For previously painted surfaces, ensure the existing paint is properly sanded and free from peeling or flaking. Remove all sanding dust with a tack cloth.

- Primer Application: Apply a high-quality primer designed for cabinets. This provides a uniform base for the topcoat and improves paint adhesion and durability. Allow the primer to dry completely according to the manufacturer’s instructions.

- Paint Application: Apply thin, even coats of cabinet paint using a high-quality brush, roller, or sprayer. Avoid applying thick coats, which are more prone to cracking and chipping. Allow each coat to dry completely before applying the next. Multiple thin coats are preferable to one thick coat.

- Final Sanding (Optional): After the paint has dried, lightly sand with very fine-grit sandpaper (320 grit or higher) to smooth out any imperfections. This step is optional but can improve the final finish’s smoothness and gloss.

- Final Cleaning: Remove all sanding dust with a tack cloth before applying a final coat, if desired.

Preventing Scratches After Painting

Post-painting protection is essential to maintain the integrity and appearance of the painted cabinets. The following measures offer effective protection against scratches.

- Protective Films: Applying clear protective films, such as those made of polyurethane or vinyl, creates a barrier against scratches and scuffs. These films are easily removable and can be replaced as needed. They are particularly beneficial in high-traffic areas.

- Clear Coat Application: Applying a clear coat of polyurethane or a similar protective sealant creates a durable, scratch-resistant layer over the paint. This adds an extra layer of protection and enhances the paint’s longevity. Multiple thin coats are recommended for optimal protection.

- Careful Handling: Educating household members about careful handling and avoiding sharp objects near the cabinets minimizes the risk of accidental scratches.

Repairing Minor Scratches

Minor scratches can be effectively repaired using touch-up paint and other methods. The following procedure Artikels a simple repair process.

- Clean the Scratch: Clean the scratched area thoroughly with a mild detergent and water. Allow it to dry completely.

- Apply Touch-Up Paint: Using a small brush or toothpick, carefully apply touch-up paint that matches the cabinet’s color to the scratch. Apply thin layers, allowing each to dry before adding more to avoid buildup.

- Smooth the Surface: Once the touch-up paint is dry, gently smooth the surface with fine-grit sandpaper (400 grit or higher) to blend the repair with the surrounding area. Remove any sanding dust with a tack cloth.

- Apply Clear Coat (Optional): For added protection and to enhance the finish, apply a thin coat of clear coat to the repaired area.

Cabinet Material and Scratch Susceptibility

The choice of cabinet material significantly impacts the overall durability and scratch resistance of painted kitchen cabinets. Understanding the inherent properties of different materials and their interaction with paint is crucial for achieving a long-lasting, aesthetically pleasing finish. This section will explore the relationship between cabinet material and scratch susceptibility, providing guidance on selecting materials and paint combinations to optimize scratch resistance.

Different cabinet materials exhibit varying degrees of hardness, density, and porosity, all of which affect paint adhesion and the overall resilience to scratches. Harder, denser materials generally provide a more stable base for paint, resulting in a more durable finish. Conversely, softer, more porous materials may be more prone to scratches and chipping, even with high-quality paint.

Material Properties and Paint Adhesion

The following table compares common cabinet materials regarding their susceptibility to scratches and their paint adhesion properties. Higher ratings indicate better performance.

| Material | Hardness | Density | Paint Adhesion |

|---|---|---|---|

| Solid Wood (e.g., Oak, Maple) | High | High | Excellent |

| Medium-Density Fiberboard (MDF) | Medium | Medium | Good |

| Particleboard | Low | Low | Fair |

| Plywood | Medium | Medium | Good |

Causes of Scratches on Painted Cabinets

Understanding the common causes of scratches allows for preventative measures and informed material selection.

Several factors contribute to scratches on painted cabinets. Addressing these factors is essential for maintaining the cabinet’s appearance and longevity.

- Sharp objects: Knives, utensils, and other sharp items can easily scratch painted surfaces.

- Improper cleaning: Abrasive cleaners and scouring pads can damage the paint finish.

- Wear and tear: Daily use and accidental impacts can lead to scratches over time.

- Poor surface preparation: Inadequate sanding or priming before painting can compromise adhesion and increase scratch susceptibility.

- Inferior paint quality: Low-quality paints are more likely to chip and scratch than high-quality, durable paints.

Material, Paint Type, and Scratch Resistance

Strategic material and paint selection significantly influences scratch resistance. The table below illustrates this concept. Scratch resistance is rated on a scale of 1 to 5, with 5 representing the highest resistance. These ratings are based on general observations and industry standards, and actual performance may vary depending on specific paint and application techniques.

| Material | Paint Type | Scratch Resistance (1-5) | Notes |

|---|---|---|---|

| Solid Wood | High-quality enamel paint with multiple coats | 4-5 | Excellent durability with proper preparation and application. |

| MDF | High-quality acrylic-urethane paint with a durable topcoat | 3-4 | Requires careful surface preparation to ensure good adhesion. |

| Particleboard | High-quality melamine paint | 2-3 | More susceptible to scratches; melamine offers some protection. |

| Plywood | High-quality acrylic-urethane paint with a durable topcoat | 3-4 | Similar to MDF; requires good surface preparation. |